Touch Screen Structures – Nowadays, many devices, machines, and instruments integrate touchscreen technology, which prevails across various industries. There are some different types of touchscreens in terms of structure, functions, and performance. But almost all touchscreen devices contain a touch detection component, a digitizer, a liquid-crystal display (LCD) and backlighting. The combination of these components allows a touchscreen device to detect touch commands as well as project images. These elements work together to enable a touchscreen device to detect touch commands and also present visuals.

Placing the touch detection component in front of the display screen enables it to detect the user’s touch position and transmit it to the touch screen controller after receiving it. The touchscreen digitizer is a component that transforms analog touch signals into digital touch signals.

Touch Screen Structures – The Liquid-Crystal Display (LCD)

The LCD, an electronic display utilizing liquid pixels as its defining feature, is essential for touchscreens to generate images. However, a touchscreen lacking an LCD won’t display images, even with a digitizer present. In touchscreen devices, a panel positioned behind the digitizer functions as the LCD. Collaborating with backlighting, the LCD brings visuals to life on the touchscreen. Since LCDs cannot emit light independently, they rely on a separate lighting system to operate. LCD touchscreens commonly employ LED backlighting, known for its longevity, energy efficiency, and powerful illumination. Some LED backlighting systems further enhance light distribution by utilizing optical fiber or light guides.

In addition to the common features mentioned above, the main four types of touchscreens in the market differ in some ways in terms of structure.

Projected Capacitive Touchscreen – Touch Screen Structures

The capacitive touch screen structures generally consists of four layers. A protective glass layer serves as the outermost layer, followed by a conductive layer, a non-conductive glass screen, and a fourth, conductive layer, which serves as the innermost layer. It uses a matrix of tiny electrodes under the glass surface. Compared with resistive touchscreens that used individual wires attached to each pixel, capacitive touchscreen offers thinner displays and higher resolution.

Projected capacitive and surface capacitive touchscreens are well-known capacitive touchscreen types. The primary difference between projected capacitive and surface capacitive touchscreens is that the latter uses two layers of electrodes whereas the former uses a single layer of electrodes.

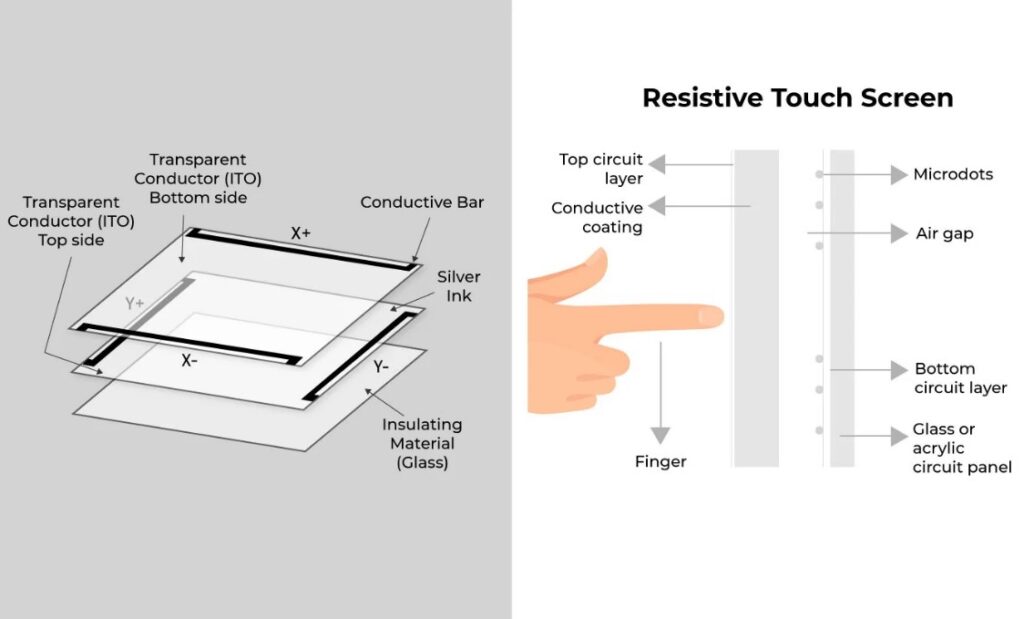

Resistive Touchscreen

Resistive touch screen structures consist of two conductive layers separated by invisible spacers. Transparent indium tin oxide (ITO) coatings cover the layers, providing both electrical conductivity and resistance. Manufacturers typically make the bottom layer from glass or film, while the top layer is mostly made of film.

Resistive touch panels come in two different structural configurations. The choice between glass or polycarbonate as the support material (part of the bottom layer) determines the differences in construction. Film/Glass is a more typical construction for resistive touch panels. The difference lies in the material of the bottom layer and the accompanying support.

Surface Acoustic Wave Touchscreen

Manufacturers construct the surface acoustic wave touch screen from a single glass sheet containing reflectors, receiving transducers, and transmitting transducers. The transmitting transducers produce ultrasonic waves that pass across the panel’s surface. The receiving transducers capture the ultrasonic waves after the reflectors have reflected them.

SAW touchscreens have a top layer composed entirely of glass. SAW touchscreens have excellent optical clarity thanks to its top layer made entirely of glass. The glass top layer of a SAW touchscreen allows for more light to enter through.

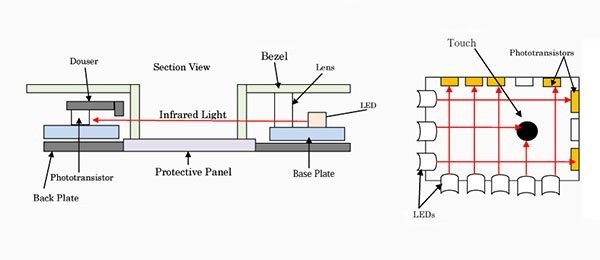

Infrared Touchscreen

An infrared touch screen comprises an LCD monitor, an IR touch frame, and an infrared touch overlay. Typically, manufacturers enclose a sheet of protective glass with an IR touch frame containing embedded infrared LEDs and photodetectors for the overlay. Subsequently, to fix the frame and transmit the infrared light emitted by those LEDs, an optical bezel of some sort will be installed between the glass and the frame.

IR LEDs generate invisible infrared beams from the optical bezel, forming grids on the surface of the overlay. Photodetectors are placed to detect interruptions of beams when touch events occur on the screen.

Top One Tech excels in offering our customers a variety of touch screen options, including projected capacitive touch screens, infrared touch screens, touch monitors, and all-in-one touch computers. Furthermore, we provide comprehensive services such as customization, production, OEM, and ODM solutions.

See Also : Our Touch Screen Products